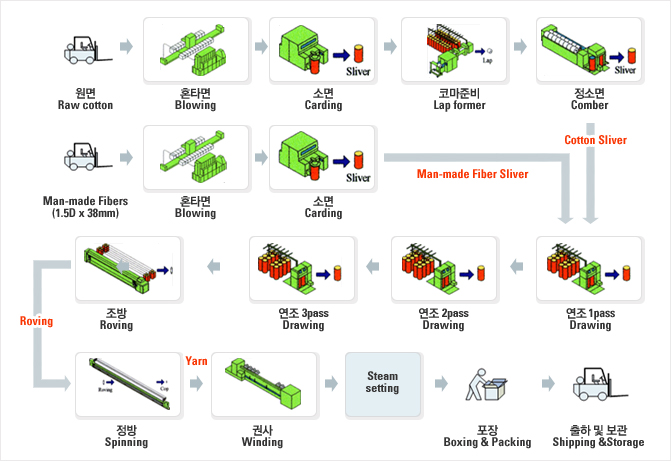

Production

Production

Process

Production

Process

* Detailed explanation will be given to you by clicking each image.

1) Blowing

| Process | Blowing |

|

|---|---|---|

| Purpose | Decreasing density of raw cotton (Spreading) Removing large impure materials (Removing) Making Ingredients evenness by blending (Blending) |

|

| Processed Product |

LAP (Chute Feed system) |

2) Carding

| Process | Carding |

|

|---|---|---|

| Purpose | Removing small impure materials Removing staple fiber ball Fiber parallelization |

|

| Processed Product |

Carding Sliver (Cotton) |

3) Lap Former

| Process | Lap Former |

|

|---|---|---|

| Purpose | Producing Lap fitted for comber process Ingredient & Quality evenness by blending raw materisls |

|

| Processed Product |

Lap (Cotton) |

4) Comber

| Process | Comber |

|

|---|---|---|

| Purpose | Removing staple fiber "Noil" Fiber straightness through combing effect |

|

| Processed Product |

Comber Sliver (Cotton) |

5) Blowing

| Process | Blowing |

|

|---|---|---|

| Purpose | Converting cellulose & polyester staple fibers into small sized state and supplying them to carding machine in a equal amount |

|

| Processed Product |

LAP (Chute Feed system) |

6) Carding

| Process | Carding |

|

|---|---|---|

| Purpose | Removing small impure materials Removing staple fiber ball Fiber parallelization |

|

| Processed Product |

Carding Sliver (Modal, Tencel, Polyester) |

7) Drawing 1st Pass

| Process | Drawing 1st Pass |

|

|---|---|---|

| Purpose | Producing blended sliver by mixing cotton with carding slivers of polyester, modal and tencel |

|

| Processed Product |

Drawing Sliver |

8) Drawing 2nd Pass

| Process | Drawing 2nd Pass |

|

|---|---|---|

| Purpose | Mixing 1st pass blended sliver evenly and reducing fixed amount deviation |

|

| Processed Product |

Drawing Sliver |

9) Drawing 3rd Pass

| Process | Drawing 3rd Pass |

|

|---|---|---|

| Purpose | Fiber straightness and producing fixed amount sliver for next step |

|

| Processed Product |

Drawing Sliver |

10) Roving

| Process | Roving |

|

|---|---|---|

| Purpose | Making proper thickness and giving minimum twist for next step |

|

| Processed Product |

Roving |

11) Spinning

| Process | Spinning |

|

|---|---|---|

| Purpose | Doing final twist process for good strength and friction-resistance |

|

| Processed Product |

Yarn |

12) Winding

| Process | Winding |

|

|---|---|---|

| Purpose | Removing defects on the yarn finally and winding yarn in the form of cone |

|

| Processed Product |

Final cone-type yarn |